We are more than proud that DYNASET Products are made in Finland, if we are more accurate, in a small Finnish town called Ylöjärvi. Our factory is constantly evolving because of the rapid growth of the company and evolving is so fast that almost any week you can see something new in our facilities. But why is our factory in Finland? We asked this directly from our founder and CEO, Reijo Karppinen.

- Finland is a good location for a factory and headquarters for many reasons. Firstly, many machinery innovations have been born in Nordic countries, such as hydraulic hammers and the idea of the auxiliary hydraulic system. Secondly, there are many small companies with small machinery fleets in Finland. These contractors are eager to develop their abilities and learn to use new pieces of equipment. You might say that when a Finnish contractor buys an expensive excavator, they want to benefit from it as much as possible. Thirdly, Finns overall are very eager to learn new things, making Finland a perfect place for research and development of new products. That is important for us because we are building the market for hydraulic equipment and it is essential to have good reference clients. Finnish contractors are wise and curious to learn how to benefit from new equipment.

High-Quality Products

Having a production facility together with headquarters also means easier quality control.

- Having our own factory means that we can plan, develop and have complete control of our processes, not forgetting the ground rules of the ISO 9001:2015 standard. One advantage of having the factory is the implementation of quality aspects in daily work. High-quality production requires personnel who constantly work with the quality aspects of our products, but it is also crucial that every DYNASET worker understands high-quality production principles. We are proud of our products, and it ensures that our workers are committed to high quality, said Production Manager Tero Ylä-Soininmäki.

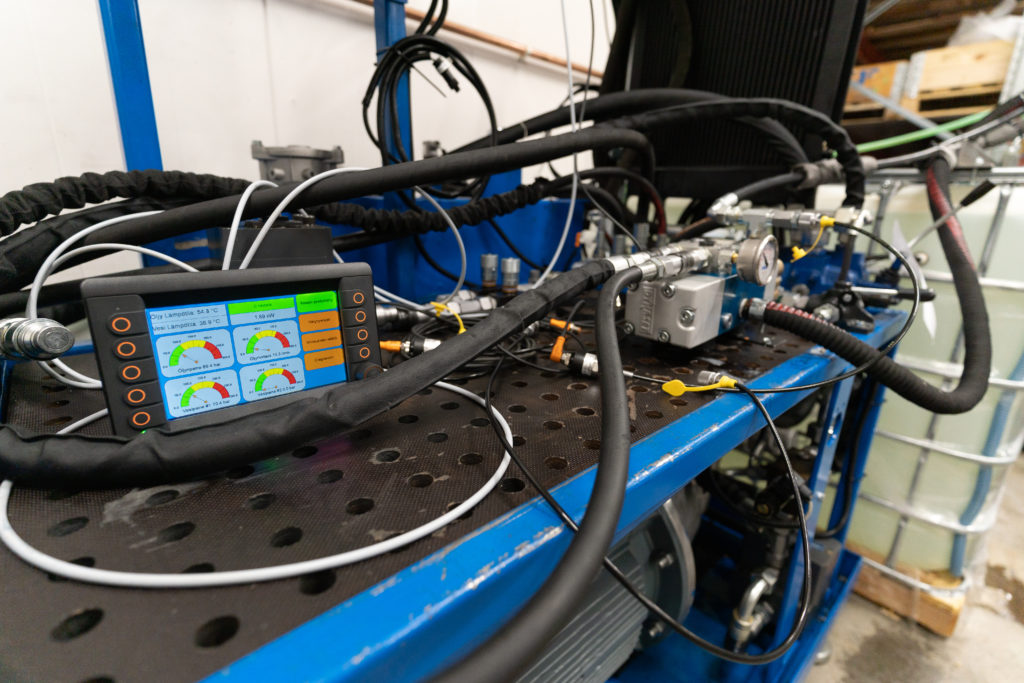

Also, endurance tests are easy to arrange when our engineers and designers can supervise them. All new DYNASET Products have such test which shows in practice how the product survives in long-term usage. The photo below is one example of these tests. The photo is from an endurance test of a new model of HDF Hydraulic Drilling Fluid Pump. The test-bench automation monitors the test and ensures systematic testing of the product.

Headquarters Full of Experts

The fact that white-collar and blue-collar workers work in the same facilities is a massive advantage in a pretty obvious way. Even though our personnel count is growing, we still know each other pretty well no matter which department we work in. We asked Samuli, one of our Area Sales Managers, what he thinks about the arrangement where headquarters is in the same building with production facilities.

- It is good that we all are working in the same building because it makes cooperation with our production fast. After all, we can have face-to-face talks with the actual workers who assemble our products. Also, it is easy to confirm things in practice.