How Does the Hydraulic Screw Compressor Work?

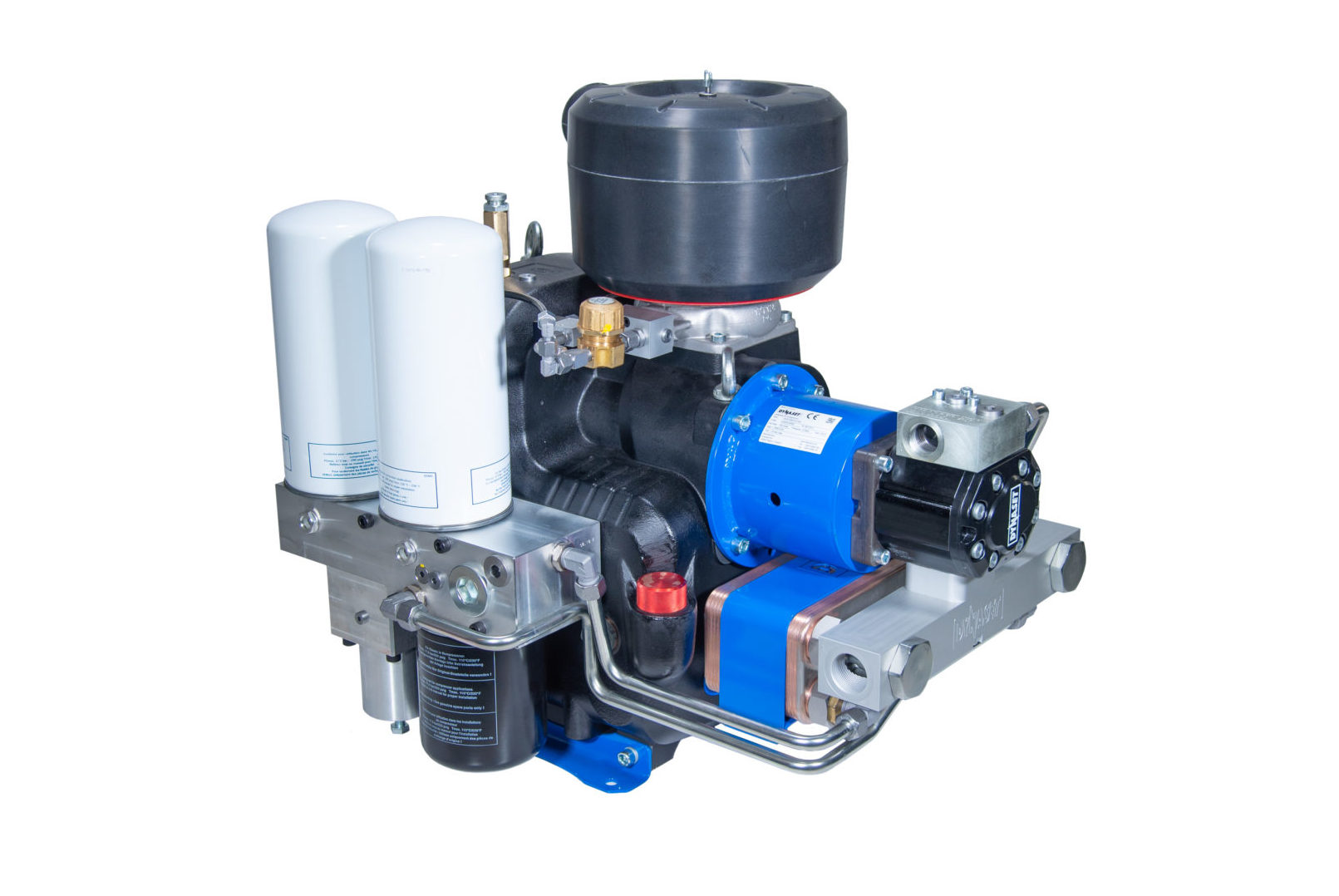

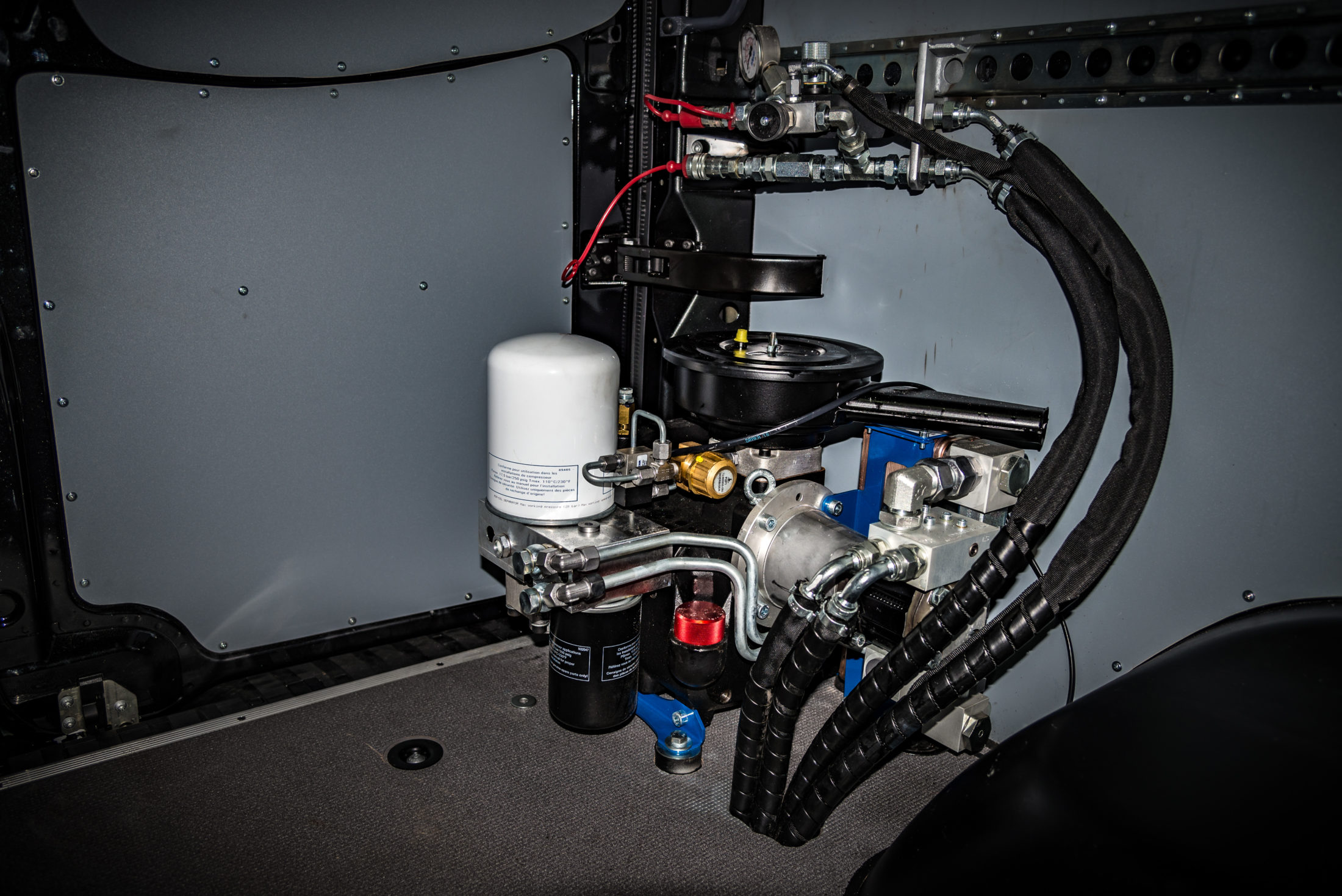

The hydraulic compressor utilizes a machine’s, vehicle’s, or vessel’s hydraulic system as its power source to produce airflow.

- Hydraulic oil flows to the hydraulic compressor’s integrated hydraulic motor through the pressure line.

- The hydraulic compressor converts hydraulic oil flow and pressure into compressed air.

- The hydraulic oil is returned to the carrier machine’s hydraulic oil tank via the return line.

- The screw compressor is equipped with an oil heat exchanger that transfers heat to the carrier machine’s hydraulic system for cooling.

- The hydraulic screw compressor can operate continuously 24/7 without stopping. It runs at idle speed when not producing airflow.