DYNASET pumps can provide pumping power for seawater, drilling fluids, disinfection fluids, chemicals, and many other fluids in almost any environment. However, it is important to know that the pumped fluid and usage environment can affect what is required from the pump. DYNASET Pumps are a great choice to be used in subsea operations because their structure withstands ambient pressure in depths as they are.

How Usage Environment and Pumped Liquid or Chemical Affects Pump’s Manufacturing Material Choices?

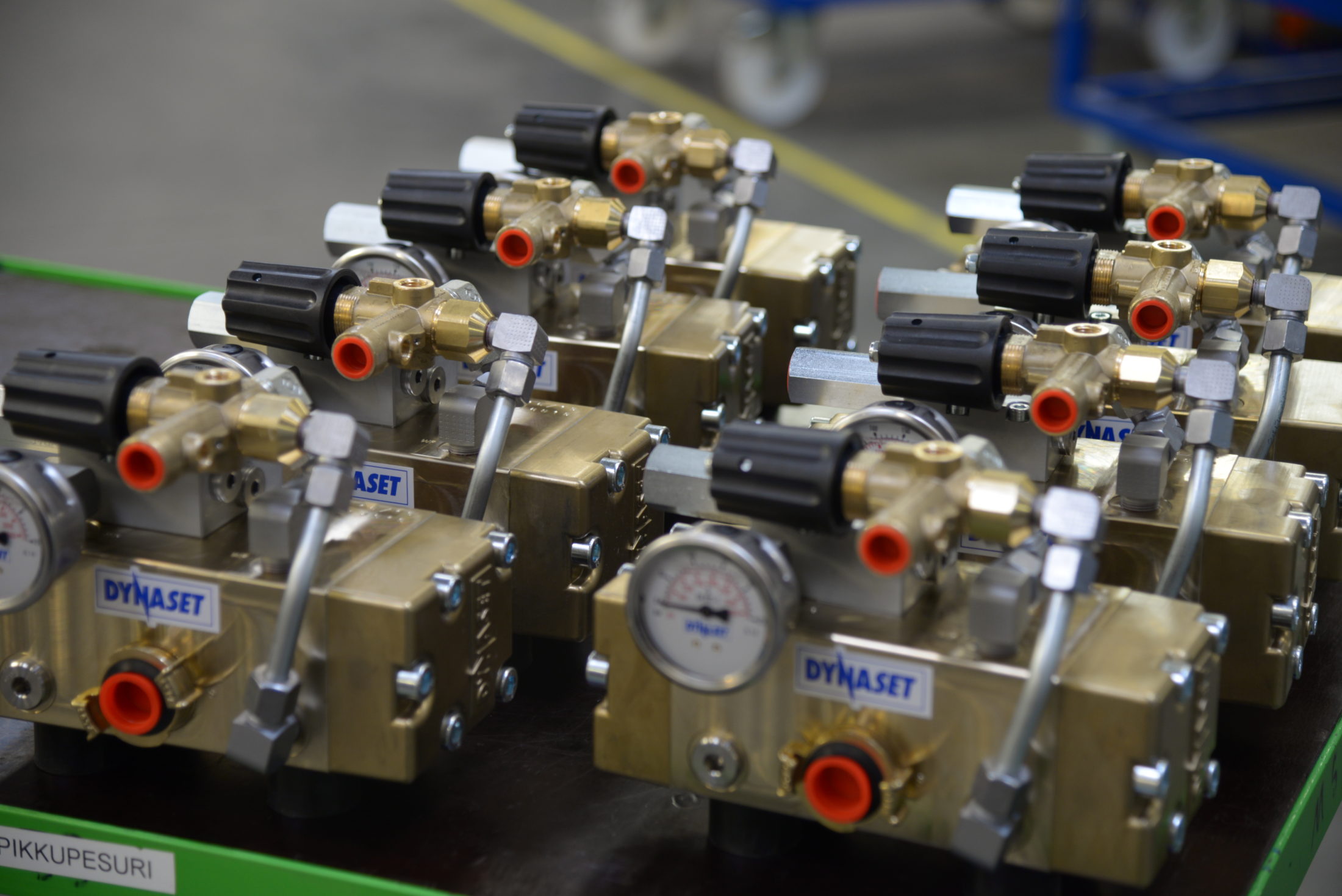

So, the usage environment can affect the material of which the pump should be made. For example, our subsea pumps’ center bodies and heads are made of stainless steel or aluminum bronze instead of aluminum as in some of the basic models. That’s because the aluminum isn’t resistant to saltwater. Also, the pumps’ inner parts are engineered to be resistant to saltwater.

Sealed or Non-Sealed Leakage Space?

All DYNASET Pumps have a leakage space that is not sealed in basic models. The pumps have small leakage detecting holes which makes the possible leaks easier to spot. The leakage space can be left open if the pumped liquid allows that, and the used hydraulic oil isn’t hazardous to the environment. In subsea conditions the open leakage space allows an ambient pressure to provide important support to the seals of the pump in the depths.

Some cases require sealing of the leakage space. That is easily done because the leakage detecting holes are equipped with threads. In subsea conditions, the sealing can be done with a pressure compensated bladder that is attached to the leakage detecting holes. The bladder prevents the leaks to get into the environment. It also provides the needed support for the seals when the ambient pressure cannot reach the seals.

Correct Materials and Maintenance for Different Chemicals

Overall, the DYNASET pumps can be used for pumping various chemicals. DYNASET Personnel and the authorized dealers can provide accurate information about the chemical resistance of the DYNASET pumps. The easiest way to find out can your fluid to be pumped with DYNASET Pumps is to contact us via the form below.