Have you heard about sequence-controlled pumps before? This article includes the basic knowledge about sequence control of DYNASET Hydraulic High Pressure Water Pumps. There is also a downloadable brochure at the end of the article.

Sequence Controlled Pumps in A Nutshell

So, a sequence controlled pump means a unit of several pumps. These pumps operate together for a common goal. In the picture below there are four DYNASET HPW 460 Hydraulic High Pressure Water Pumps connected to each other. This combination works as one unit which has one set of hydraulic lines. These pumps’ water outputs are often compound into one output during the installation.

But what the “sequence” stands for? The sequence refers to the way of how these pumps work together. There is a chart below that explains the meaning of sequences. In the beginning, when the system is started, all four pumps are equally supplied with the hydraulic flow at low output pressure. When the output pressure increases to a certain level and the system has reached its maximum power point, one of the four pumps is shut down and only the three remaining pumps are supplied with the hydraulic flow. Having now fewer pumps to supply, the systems output pressure can increase further, while staying always at the maximum power point.

Speed VS Power

So, each sequence means that a pump turns off which means that the power of the hydraulic system can be used for increasing the water pressure with the pumps that are still running. But why use four pumps instead of one if after all only the last pump is going to build up the final pressure? The answer is speed.

Let us explain. In the beginning, where all pumps are running together, the water output flow can be higher than one pump’s max output water flow is. So in practice, this means that the first sequences are faster than the latter sequences.

But why we don’t just push it through with all four pumps? Fast and easy, right? The reason is the increasing demand for pressure in the task at hand.

For example, let’s imagine that you have a metal pipe, and you want to seal the pipe by squeezing it from the middle. So, you don’t want anything to go through the pipe anymore. For that, you have to squeeze the pipe really hard via a tool like a press. At first, the press can squeeze pipe quite easily and fast but when the process goes towards the end the press will need more power aka pressure for the squeezing.

In this case, the four pumps are providing the pressure and flow for the rapid movement of the pressing. When the pressure demand goes higher, the hydraulic system’s power is used for fewer pumps which decreases the speed but adds power to the movement.

So if the hydraulic system cannot provide enough power for four pumps to reach the maximum pressure, with sequences it is possible to allocate the power as well as possible.

Where To Use These?

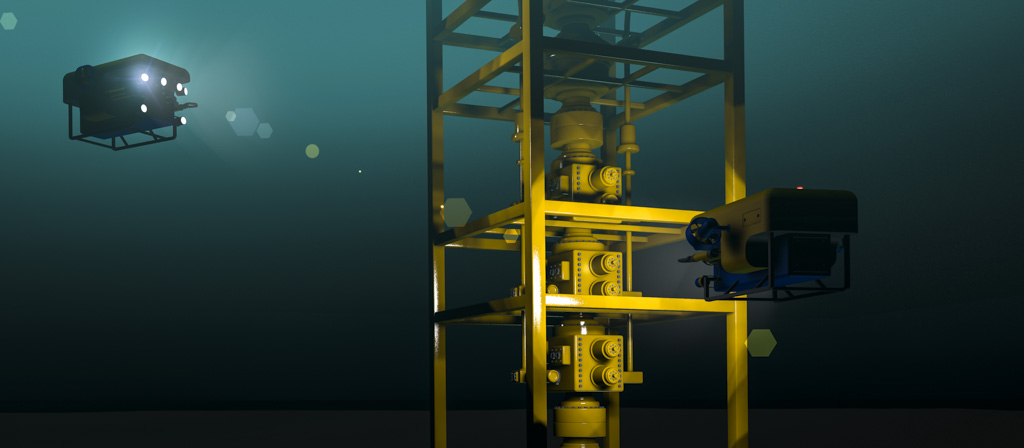

So, sequence pumps are perfect for cases where is limited hydraulic power and the task requires much power. For example, valves that require much pressure for closing, like valves of blowout preventers (BOP) are common applications. Also, different kinds of tools like powerful shredders, combi tools, and spreaders can be powered with sequence pumps. This is used for example in underwater remotely operated vehicles (ROV) tooling applications.